Shop

Order Samples

Resources

Commercial

3D LAMINATE FINISHES

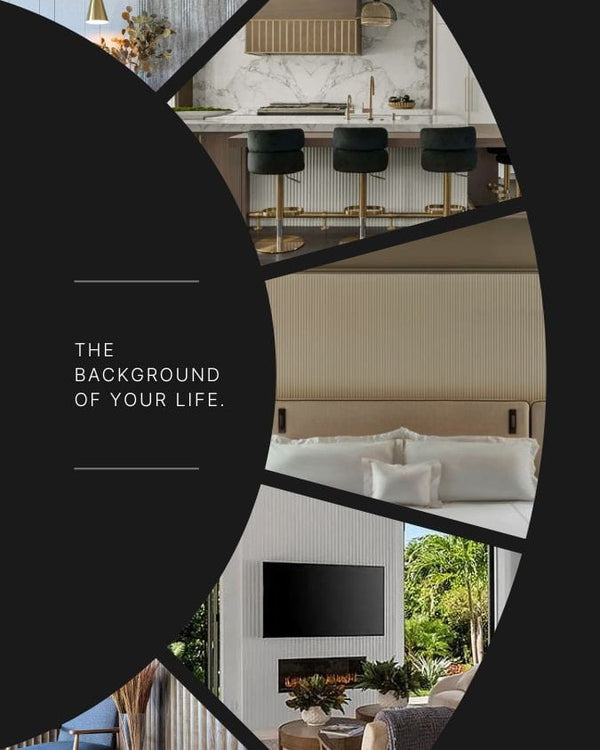

White Oak

As a versatile and durable 3D laminate option, the White Oak effect 3DL offers a combination of style and resilience. 3D laminate adds a unique touch to the classic white oak design, making it a more durable choice for any space. With its low maintenance and enhanced aesthetic, White Oak 3DL is an excellent investment for long-lasting beauty and functionality.

White Oak 3D Laminate, also known as Rigid Thermofoil (RTF), is a type of surface material used to mold over an MDF substrate using heat and pressure to create a seamless, durable, and visually appealing finish.

3D Design: 3D Laminate can be molded around edges and contours, providing a seamless panel that eliminates the need for edge banding.

Variety of Finishes: 3D laminate is available in a wide range of colors, textures, and patterns, including wood grain, stone, linen, and metallic.

Durability: Resistant to moisture, heat (up to 150 degrees), and scratches, making it suitable for high-traffic areas.

Cost-Effective: Generally more affordable than solid wood or stone finishes while still offering a high-quality appearance.

Click to View PDF's Below:

Care & Maintenance:

To maintain the longevity of our 3D Wall Panels, it is important to follow these care instructions. Avoid placing hot objects exceeding approximately 140 °F directly on the surface. Regular dusting and occasional cleaning are recommended to prevent dirt buildup. For stains, use a warm diluted soap solution with a non-abrasive sponge. Suitable cleaning products include Windex, Simple Green, Fantastik, or a 10:1 Water/Bleach solution. Persistent stains can be removed using a cleaner such as Clorox® Clean-Up®. After cleaning, rinse with clean water and dry with a soft, non-abrasive cotton cloth. Test cleaning products on a small, hidden area first to ensure they are compatible and won't damage the surface.

Storage:

Keep panels in a climate-controlled environment for 48 hours prior to installation with consistent humidity levels between 25% and 55% and temperatures between 60°F and 75°F to prevent moisture-related expansion and contraction.

Recently viewed products

White Oak

MADE IN AMERICA

Get 5% Off Your First Order

Sign up now for exclusive discounts and insider updates!