Shop

Order Samples

Resources

Commercial

3D LAMINATE FINISHES

Carbon Slate (DISCONTINUED)

*This product has been discontinued and is no longer available for purchase.*

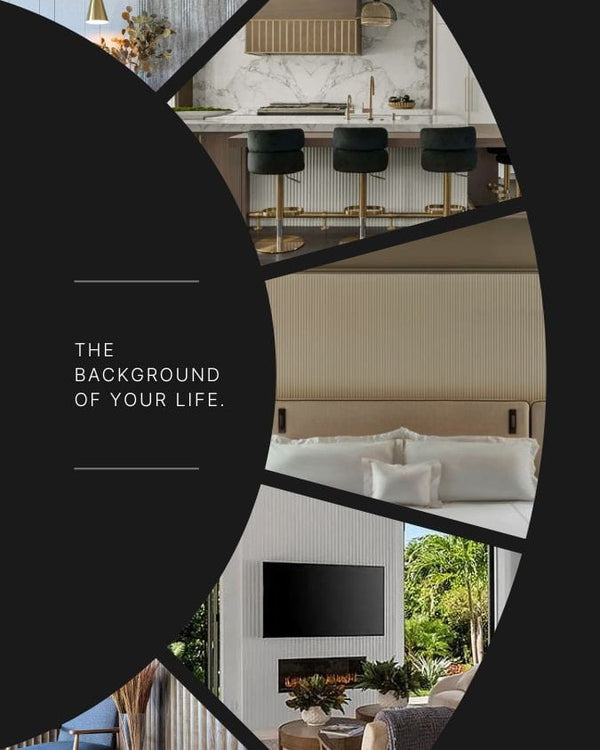

Experience a modern and sleek metallic look with our Carbon Slate 3D Laminate finish. Perfect for achieving a unique and textured design on our 3D wall paneling patterns. Get the sophisticated and innovative look you desire with Walston Architectural Products.

Carbon Slate (DISCONTINUED) 3D Laminate, also known as Rigid Thermofoil (RTF), is a type of surface material used to mold over an MDF substrate using heat and pressure to create a seamless, durable, and visually appealing finish.

3D Design: 3D Laminate can be molded around edges and contours, providing a seamless panel that eliminates the need for edge banding.

Variety of Finishes: 3D laminate is available in a wide range of colors, textures, and patterns, including wood grain, stone, linen, and metallic.

Durability: Resistant to moisture, heat (up to 150 degrees), and scratches, making it suitable for high-traffic areas.

Cost-Effective: Generally more affordable than solid wood or stone finishes while still offering a high-quality appearance.

Click to View PDF's Below:

Care & Maintenance:

To maintain the longevity of our 3D Wall Panels, it is important to follow these care instructions. Avoid placing hot objects exceeding approximately 140 °F directly on the surface. Regular dusting and occasional cleaning are recommended to prevent dirt buildup. For stains, use a warm diluted soap solution with a non-abrasive sponge. Suitable cleaning products include Windex, Simple Green, Fantastik, or a 10:1 Water/Bleach solution. Persistent stains can be removed using a cleaner such as Clorox® Clean-Up®. After cleaning, rinse with clean water and dry with a soft, non-abrasive cotton cloth. Test cleaning products on a small, hidden area first to ensure they are compatible and won't damage the surface.

Storage:

Keep panels in a climate-controlled environment for 48 hours prior to installation with consistent humidity levels between 25% and 55% and temperatures between 60°F and 75°F to prevent moisture-related expansion and contraction.

Recently viewed products

Carbon Slate (DISCONTINUED)

MADE IN AMERICA

Get 5% Off Your First Order

Sign up now for exclusive discounts and insider updates!