Shop

Order Samples

Resources

Commercial

From Sample to Space: How to Choose the Right Wall Panel Finish

April 16, 2025 3 min read

From Sample to Space: How to Choose the Right Wall Panel Finish

Selecting the perfect wall panel finish can feel daunting—between light variables, surrounding materials, and brand‑color requirements, the sample that looks gorgeous online can read totally different once it arrives in your hands. That’s why every successful project begins with tangible wall panel samples. In this guide, we’ll walk you through a proven, five‑step process Walston Architectural Products uses with architects, interior designers, and homeowners to ensure the finish they fall in love with on Day 1 is the same finish that delights them after installation.

1. Why Order Wall Panel Samples First?

Holding the material matters. Screens distort texture, color, and sheen, so the only way to judge a finish accurately is to see—and feel—it in person.

Key benefits of requesting samples early:

-

True‑to‑life color – Digital renderings can’t capture subtle undertones and true colors.

-

Surface tactility – Texture depth on fluted wall panels or micro‑reeded profiles is best understood by touch.

-

Project buy‑in – Physical samples help stakeholders visualize the final space, speeding approvals.

-

Reduced re‑order risk – Confirming a finish upfront prevents costly change orders once panels enter production.

2. Comparing 3DL Finishes vs. Real Wood Veneers

Choosing between a cutting‑edge 3DL finish and a traditional veneer boils down to performance needs, environmental goals, and aesthetic priorities.

| Criteria | 3DL Finishes | Real Wood Veneer |

|---|---|---|

| Durability | Highly resistant to moisture, stains, and impacts—ideal for high‑traffic corridors. | Prone to scratching and requires periodic resealing. |

| Consistency | Uniform color and grain match across every panel. | Natural variation—beautiful but harder to control from batch to batch. |

| Maintenance | Wipe with mild detergent; no refinishing needed. | Needs careful cleaning; touch‑ups may require sanding and refinishing. |

| Sustainability | Uses less wood fiber and emits low VOCs. | Harvested wood; sustainability depends on sourcing. |

| Cost | Predictable, mid‑range pricing. | Often higher due to raw material grading. |

Bottom line: If the project demands predictable performance and budget clarity, specify 3DL finishes. For boutique spaces where natural character is worth the maintenance, a veneer may be appropriate.

3. Reading Lighting & Color in Your Space

Lighting drastically influences finish perception. Follow this three‑point checklist when evaluating samples on‑site:

-

Test in multiple light sources

‑ View during morning daylight, afternoon sunlight, and under installed artificial fixtures (3000–4000 K).

‑ Observe how cool LEDs vs. warm incandescent bulbs shift undertones in oak or walnut 3DL films. -

Rotate the texture orientation

‑ Fluted and slat wall panel profiles cast shadows; rotate samples vertically and horizontally to preview light play. -

Compare against adjacent colors

‑ Hold the sample next to painted walls, flooring, and upholstery. Neutral greige may read pink beside cooler gray carpet.

‑ Tape the sample on the intended wall plane to view from normal sightlines.

Day‑to‑Night Snapshot Capture smartphone photos of each sample under daylight and evening lighting. Share with stakeholders to document shifts before final approval.

4. Pairing Finishes with Furniture & Flooring

Successful palettes balance contrast and continuity:

-

Match Grain Direction – Align vertical grains on reeded wall panels with hardwood‑floor planks for a cohesive rise‑and‑run effect.

-

Contrast Sheen – Pair matte stone‑look 3DL with satin metal fixtures so every surface can shine on its own terms.

-

Echo Accent Colors – If branding calls for sage green millwork, choose a walnut 3DL whose warm undertone complements rather than competes.

Finish Families to Know

-

Wood Tones – White Oak, Charleston Oak, Walnut, and Black Walnut provide timeless warmth for corporate, hospitality, and residential markets.

-

Stone Effects – Charcoal Limewash and Calacatta Gold add luxury without structural weight.

-

Textile & Linen Looks – Subtle weave linen patterns soften retail dressing rooms and spa suites.

5. The Final Checklist Before You Place the Order

-

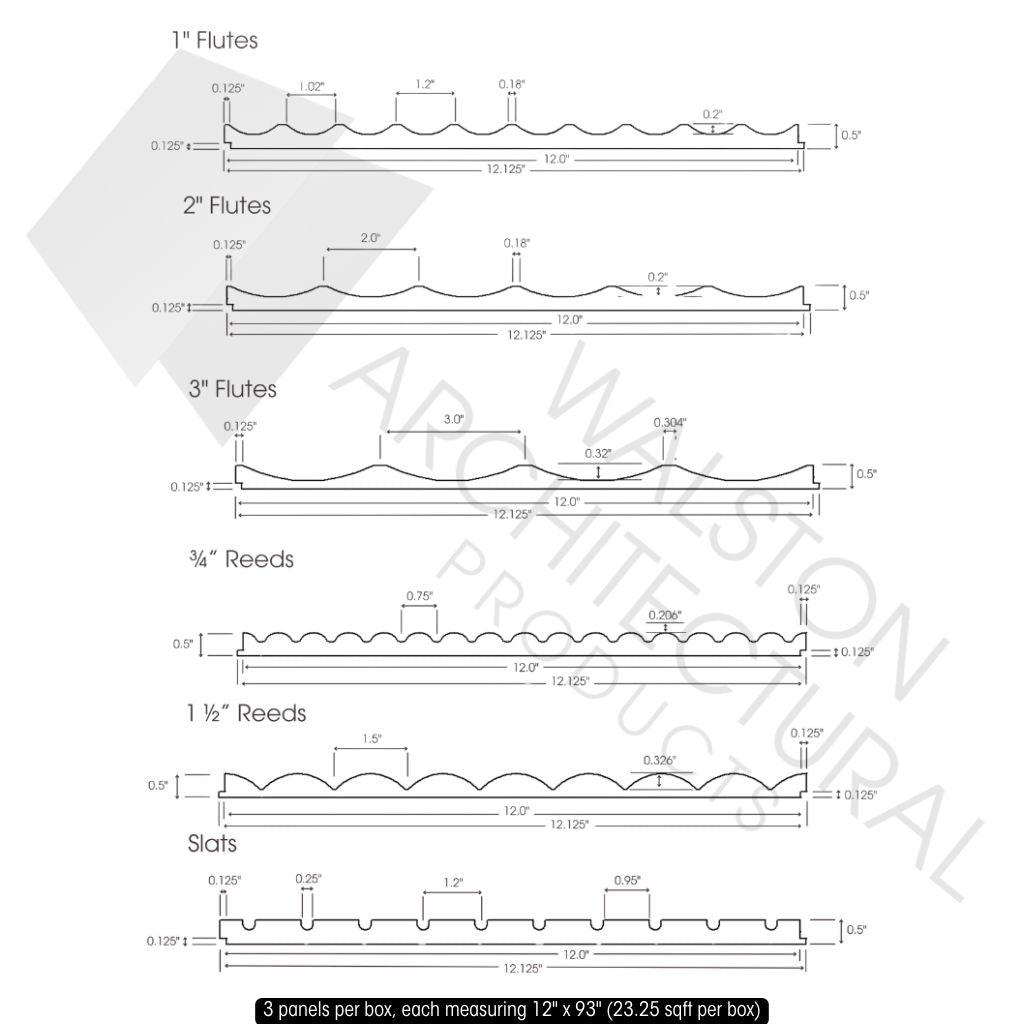

Confirm Panel Profile – Fluted, reeded, or slat—profile choice affects light, shadow, and installation method.

-

Verify Quantity & Yield – Account for cut‑outs, door elevations, and waste (5–8 %).

-

Sign Off on Production Sample – Walston offers 8" x 8" individual samples or a convenient sample pack.

-

Schedule Lead Times – Standard paintable pre-primed wall panels and 3DL wall panels ship in 1-3 business days; custom orders may require 6 weeks.

-

Plan Installation Logistics – Coordinate panel delivery with installer availability; acclimate panels 48 hours on‑site.

From Sample to Space—We’re With You Every Step

Choosing finishes isn’t just a design decision; it’s a strategic investment in the look, feel, and performance of your environment. Walston Architectural Products manufactures every interior wall panel in Kansas City, Missouri, combining precision‑routed MDF cores with premium 3DL finishes tested for commercial durability. Whether you’re specifying wood wall paneling for a flagship retail build or selecting a single headboard for a boutique suite, our sample‑to‑space workflow eliminates guesswork.

Ready to hold the possibilities in your hand?

Order our wall panel samples today, or schedule a virtual consult to review finishes on camera. Your perfect texture is only a sample away.

MADE IN AMERICA

Get 5% Off Your First Order

Sign up now for exclusive discounts and insider updates!